Can you digitize quality inspection paperwork in aircraft heavy maintenance in 2024?

.png)

Aircraft mega pit stop

The 2019 episode of the Mega Pit Stops series tells a fascinating story of the heavy maintenance of the Airbus A330-300 aircraft. The action happens on Malta in one of the Lufthansa Technik maintenance facilities where during a 40-day overhaul the 170-ton aircraft is taken apart by a team of more than 100 people. The crew dismantled the entire cabin, removed engines off the wings, checked, cleaned, repaired, or replaced every part, and finally put everything back together one day ahead of schedule.

Paperwork

The movie tells us that there are north of 10,000 job cards involved in completing the full scope of work.

Each morning or a day before normally we schedule what work needs to be done and every job has its job card number and tasks related to it

— says one of the line leaders of the facility

An aircraft maintenance job card, also known as a work order, is a document that outlines the specific tasks, procedures, and instructions required to perform maintenance, repair, or inspection on an aircraft. It serves as a detailed guide for the maintenance personnel, providing essential information to ensure that the work is carried out correctly, efficiently, and in compliance with regulatory requirements.

Digitization opportunity

Focus on inspection first

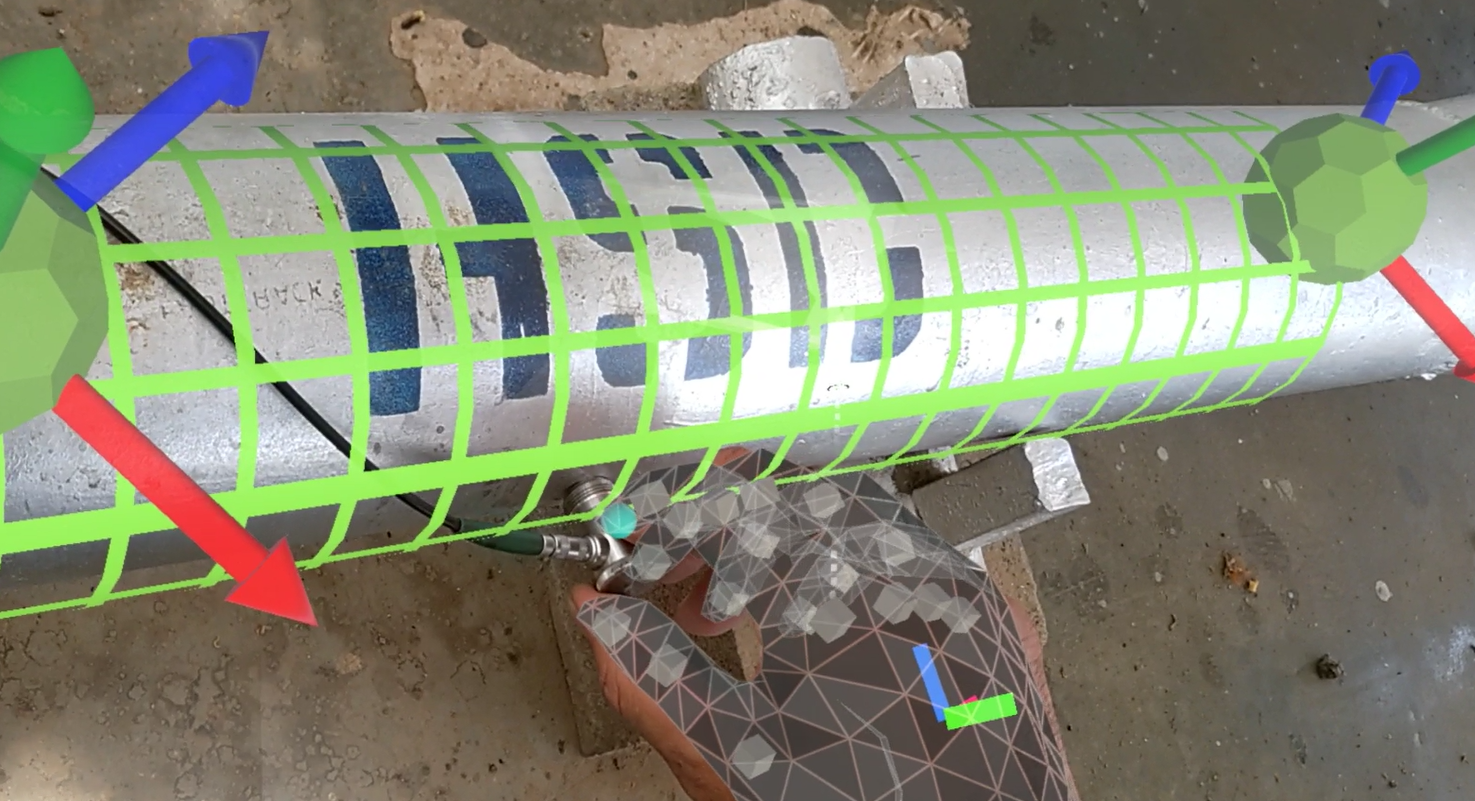

While not questioning strict record-keeping maintained for the sake of safety, we are asking a question, whether at least some of those job cards could be made portable and accessible through the AR headset?

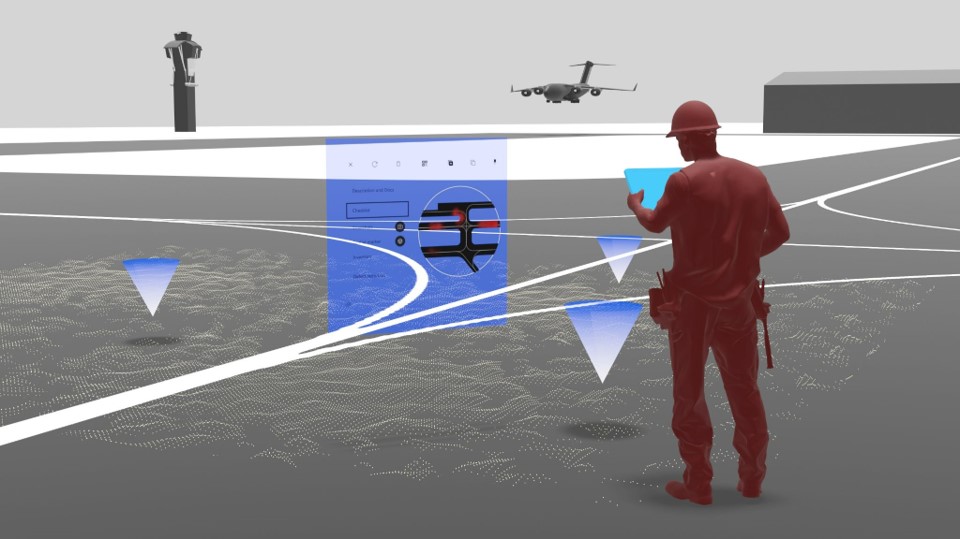

There are multiple generic capabilities of AR, however, in this case, we emphasize mobility and spatial awareness. The aircraft is large (both overall length and wingspan of A330-300 are more than 200 ft or 60m). Add a path to the office and different workshops and think about 10,000 job cards that need to be filled in eventually before being carried around by 100+ people for more than a month.

We argue that the MRO crew could use augmented reality for just two activities: receiving inspection and repair confirmation/closing job cards.

Inspection. Any initial diagnostics is better with AR. You could just snap a picture of anything you need to report and thanks to spatial awareness headset will automatically attribute the record to the required location or subsystem. This is done paperless and hands-free so you don't need to carry anything with you besides the tools.

Repair confirmation. After the work is completed, the job card needs to be marked accordingly. Technicians could do this via the headset again not only avoiding carrying paper and looking for the right document by also attaching pictures of the completed work arguably increasing the reliability of the quality records and thus safety.

Is paper good or bad?

The movie shows piles of printed job cards several times, however, we understand that paper is a double-edged sword. Some components (e.g. engine blades and many others too) are indeed so important that you want several people to sign on physical document and videotape them doing this — regulation might not let the paper go away soon (or ever).

However, do you want to do this uniformly with all documents or some may start going digital? What happens with records after the job is done? Will anyone re-enter the data in the system (duplication of effort) or if not, how will you analyze the data when needed in the future?

Applicability

We took the liberty to rank various aircraft systems by the applicability of AR-enhanced inspection based on our knowledge of MRO and the capabilities of AR.

High: Airframe, Landing Gear, Hydraulic Systems. The larger the component is the better because the location of the damage starts to matter more. The airframe itself is the perfect candidate.

Medium: Engine, Cabin Refurbishment, Painting. The cabin is large but relatively less complex. The engine is very complex but not so large.

Low: Fuel Systems, Avionics and Electrical Systems, Component maintenance. The fuel tank is a dark confined space, the headset will hardly work there at all.

How Apple Vision Pro that entered the market in 2024 will impact this development remains to be seen.

Part 145 regulation

The same inspection techniques could be applied in both line and base maintenance. Chapter 145.A.45 Maintenance data of the December 2022 revision of the EASA Part 145 regulation mentions the following:

(e) The organisation shall provide a common work card or worksheet system to be used throughout the relevant parts of the organisation ... Work cards and worksheets may be computer generated and held in an electronic database that is adequately protected against unauthorised alteration, and for which there is a backup electronic database which shall be updated within 24 hours after an entry is made to the main electronic database.

Maintenance organizations may establish their own approach to record-keeping as long as it fulfills the purpose of maintaining the continuing airworthiness of the aircraft. The proposed AR system falls in the category of computer-generated.

Conclusion

The Lufthansa Technik facility in Malta is gorgeous, we've been there in 2019 when Spiral Technology became one of the winners of the LHT startup challenge conducted in the Innovation Bay. Mega Pit Stop documentary is worth watching for hobbyists and professionals alike.

The MRO job card system could be enhanced by digitally mapping documents to the respective locations on the aircraft and making them accessible via the AR headset. Inspection records could be supplemented with pictures and videos made with the headset improving the quality of evidence collected. Finally, repair could be confirmed and the job card closed through the same interface decreasing the turnaround time (TAT) of the aircraft.

.svg)

.svg)

.png)

.png)

.png)

.png)

.png)