Quality Where Work Happens

By bringing inspection directly to the shop floor through smartphones and tablets, advanced computer vision makes quality control portable, flexible, and accessible anywhere work is performed.

Press enter or click to view image in full size

AVIS — Automated Visual Inspection System

For the past 7 years, our team at Spiral Technology has worked on quality control solutions across industrial manufacturing — from aerospace composites and wind turbine blades to precision machine components and non-destructive testing. We’ve seen firsthand how OEMs navigate the tradeoffs between accuracy, efficiency, and the organizational challenges of digitizing legacy processes.

The previous article discussed the challenges of quality control in high-mix, low-volume manufacturing. Here, we focus on how those challenges can be addressed with today’s technology. Rather than treating inspection as an immovable checkpoint, we look at how mobility and software can bring quality assurance closer to where the work is actually performed.

Turning Phones into Precision Instruments

Smartphones and tablets are already common on the shop floor, used for everything from work instructions to logging production data. Extending that same mobility to inspection is a natural progression. In the past, inspection depended on fixed stations because cameras, sensors, and computing resources were tied to dedicated setups. Now, mobile devices themselves are powerful enough to run advanced vision models directly. By equipping the tools people already carry, we enable inspectors to capture data and verify assemblies wherever the need arises — without relying on fixed sampling points or specialized rigs.

Press enter or click to view image in full size

Portable inspection, illustrative

Defect Types in Scope

The system is designed to recognize a range of issues that frequently challenge inspectors in high-mix environments. Beyond simple presence checks, it verifies configuration, placement, and surface condition with digital consistency. In practice, that means it can detect:

- missing component

- extra / unwanted component

- misplaced component

- misaligned component

- FOD / surface defect

- erroneous marking

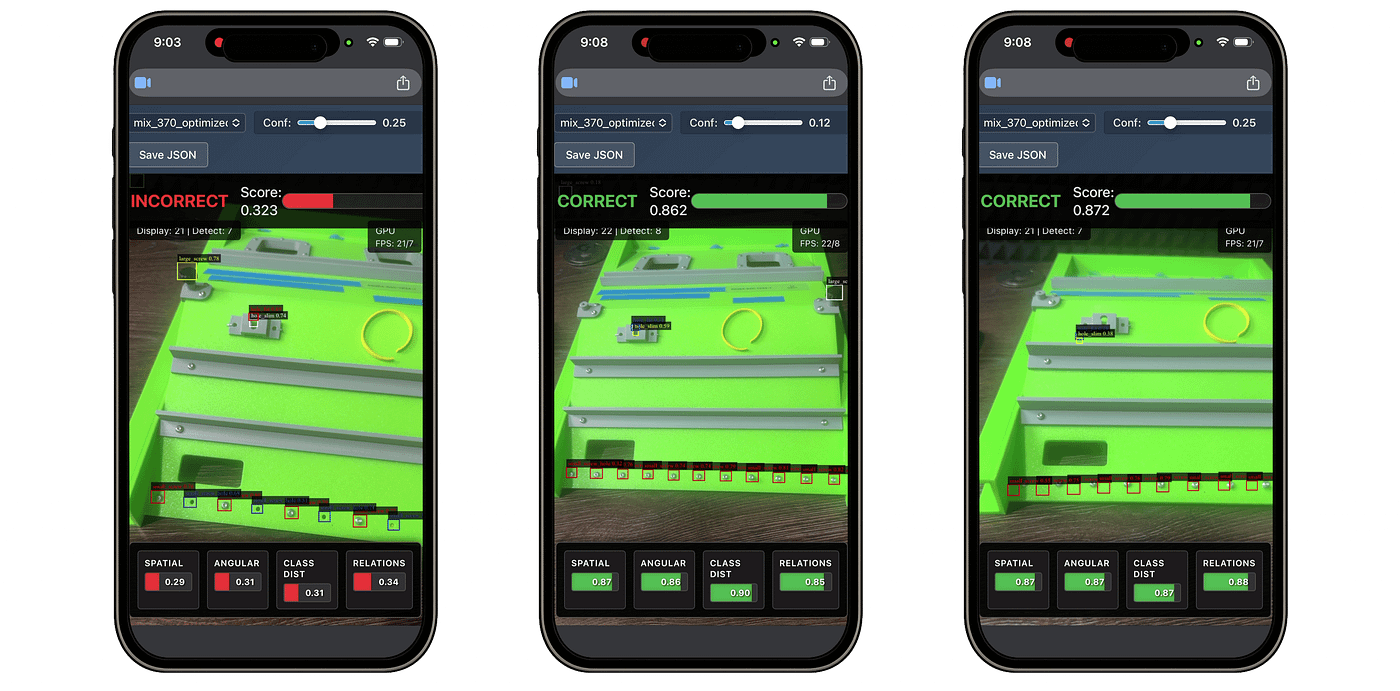

In the first test scenario, the correct configuration is defined as a screw in every even position and an empty hole in every odd position.

Press enter or click to view image in full size

Correct configuration, test scenario, zone 1

In the video, the technician removes a screw. The system immediately reflects the change, lowering the correctness score. When the screw is replaced, the score recovers. Adding an extra screw where it does not belong again triggers a drop until the proper configuration is restored.

Assembly correctness checking, test scenario: missing component, extra component

The example continues with a different section of the assembly. Here, correctness requires a black knob on the left (never on the right) and an asymmetric keyhole bracket in its designated orientation.

Press enter or click to view image in full size

Correct configuration, test scenario, zone 2

When the bracket is flipped upside down, the system flags the issue at once, showing a drop in the score to indicate misalignment.

Assembly correctness checking, test scenario: misaligned component

Moving the black knob from the left-hand side to the right is also detected immediately. Instead of a score change only, the system highlights the misplaced part, signaling the error in real time.

Assembly correctness checking, test scenario: mispalaced component

Foreign objects and surface defects represent another major class of nonconformance. Assemblies must remain free of debris, and coatings or finishes must show no scratches, burrs, cracks, or pinholes. While these flaws appear in many forms, the requirement is clear: any anomaly must be identified early, whether familiar or unexpected.

Below are three examples where different methods were applied to highlight surface damage.

Foreign object on the surface

Paint pinhole defect

Surface anomalies

Each of these categories corresponds to common, high-impact failure modes in assembly. By digitizing the inspection process, the system ensures these defects are flagged reliably, documented automatically, and made visible early — when correction is fastest and least costly.

Inspection in the Flow of Work

The real strength of this approach is not just portability but integration into daily routines. In a large composite assembly, for example, inspectors can move freely around the part, documenting alignment or verifying component placement without bringing the structure to a fixed station. In electronics, a technician can check soldered subassemblies right at the bench, before they are passed downstream.

Because the inspection system runs on general-purpose hardware, it adapts to different contexts with minimal friction. A phone can be handheld to reach into cramped spaces, or it can be mounted on a tripod to act as a semi-fixed station when repeatability is critical. In both cases, the underlying software applies the same digital rules.

Benefits That Matter to Engineers

Engineers and production managers often ask a simple question: beyond convenience, what does this approach deliver? The answer comes down to three main themes.

First, operational accuracy improves. When every build is verified against its intended configuration in real time, the risk of escapes — defective units reaching the customer — falls dramatically. That reduction translates directly into fewer costly reworks and less wasted labor.

Second, decisions happen faster. A pass/fail signal with a documented reason means teams don’t wait hours for inspection reports or argue over ambiguous findings. They know immediately whether to continue, correct, or rework.

Third, results become repeatable. Manual inspection often suffers from variability between inspectors, especially under pressure. A digital system enforces the same criteria every time, ensuring that quality doesn’t depend on who happens to be on the floor that day.

Additional gains follow naturally: flexibility of deployment on existing hardware, automatic creation of timestamped audit records, and integration with enterprise systems for compliance. But the essence is that inspection stops being an obstacle and becomes a facilitator of production flow.

Why It Fits HMLV

High-mix environments strain traditional inspection methods. Short runs make it uneconomical to spend weeks setting up fixed systems, while constant variation overwhelms manual inspectors. A mobile, software-first approach resolves both challenges:

- Fast to reconfigure — adapts to new part families without lengthy engineering cycles.

- Consistent by design — applies digital inspection rules uniformly across operators and shifts, reducing variability.

- Cost-efficient — runs on existing mobile devices, avoiding the capital expense of dedicated hardware.

Together, these advantages align the economics of inspection with the realities of HMLV production. Quality assurance keeps pace with manufacturing agility — and, with smartphones as delivery vehicles for advanced vision models, quality control finally happens where the work is done.

Technical Parameters

Engineers evaluating such systems expect concrete specifications, not just promises. Performance metrics provide a clear picture of what’s feasible.

- Accuracy: Positional tolerance within ±10 mm for component presence and alignment checks; reliable recognition of text characters down to 3 mm in height.

- Scale: Effective for features as small as 5 mm and assemblies as large as 5 meters.

- Setup Speed: New part families configured in under 24 hours; new variations ready in as little as an hour.

- Hardware: Operates on smartphones and standard HD cameras; no need for dedicated scanners.

- Connectivity: Runs without an internet connection; logs inspections locally and syncs when possible.

- Compliance: Exports audit-ready records, supporting ISO 9001 and AS9100 frameworks.

These numbers reflect a balance between precision and practicality: good enough to catch what matters in production, fast enough to keep pace with HMLV changeovers.

Conclusion

The story of manufacturing has always been about shifting the balance between people, tools, and processes. In the past, inspection was isolated and specialized. Now, it is mobile, accessible, and embedded in the flow of work.

By turning everyday devices into precision instruments, advanced computer vision doesn’t just close the gap left by manual inspection or rigid automation. It reshapes the role of quality control entirely — from a compliance burden to an active enabler of speed, consistency, and competitiveness.

Next, we turn to the technology itself: how it works, and why it finally makes portable, adaptable inspection feasible.

Learn more about AVIS — portable computer vision for high-mix, low-volume manufacturing. Verify component configuration, markings, and surface condition in real time using cameras your teams already own.